Overview of PPC series air box pulse bag filter

PlenumPulse is a high-efficiency bag filter developed by Tianjin Cement Industry Design and Research Institute on the basis of introducing the technology of Fuller, absorbing the technical advantages of German dust collectors and combining the actual national conditions of China. This series of bag dust collectors, which combines the advantages of various types of dust collectors, such as the back blowing pulse of the fan in separate rooms, overcomes the shortcomings of insufficient kinetic energy intensity when back blowing in separate rooms, thus expanding the scope of use of bag dust collectors, improving the efficiency of dust collection, and extending the service life of filter bags. It can not only purify ordinary dusty gas, but also handle inlet concentration up to 1300g/m ² It has become a finished product recovery equipment matched with 0-Sepa powder concentrator and vertical mill. Under the new national environmental protection standard (emission concentration, thermal equipment<100mg/m ³, Ventilation equipment<50mg/m ³), It is widely used not only in the cement industry, but also in the power, chemical, metallurgical and steel industries.

working principle

The body of the air box pulse bag dust collector is divided into several box areas, each box has 32, 64, 96, 128 bags, etc. And there is a lift valve driven by an air cylinder on the outlet pipe at the side of each box. When the dust collector filters the dusty gas for a certain time (or the resistance reaches the preset value), the dust removal controller will send a signal. The poppet valve of the first chamber starts to close to cut off the filtered air flow. Then the pulse valve of this box is opened, and compressed air of more than 5kg/cm2 is flushed into the air cleaning chamber to remove the dust on the filter bag. When this action is completed (about 6~15 seconds), the poppet valve will be reopened, so that the filtering work for each chamber can be carried out again and the above requirements will be followed one by one until all the ash is removed. The air box type pulse bag dust collector adopts the separate box type dust removal, and the dust removal shall be carried out by box isolation and rotation. The pulse blowing width and ash cleaning cycle of each dedusting chamber are automatically and continuously carried out by the ash cleaning program controller, thus ensuring the effect of compressed air ash cleaning. The whole box design uses the inlet and inlet header structure, and the ash particles can be extended under the inlet header. The incoming flue gas containing dust can directly enter the expanded ash material to achieve the effect of pre dust collection, and the horizontal straight pipe that is easy to block can be removed. Therefore, the air box pulse bag dust collector can not only handle the general concentration of dust laden gas, but also handle the high concentration of dust laden gas up to 1300g/m3.

Since the dust collector uses a 2 inch and a half (inch) large pulse valve to blow back the dust, when changing the bag, open the top cover and directly draw out the filter bag, which is simple and convenient to maintain.

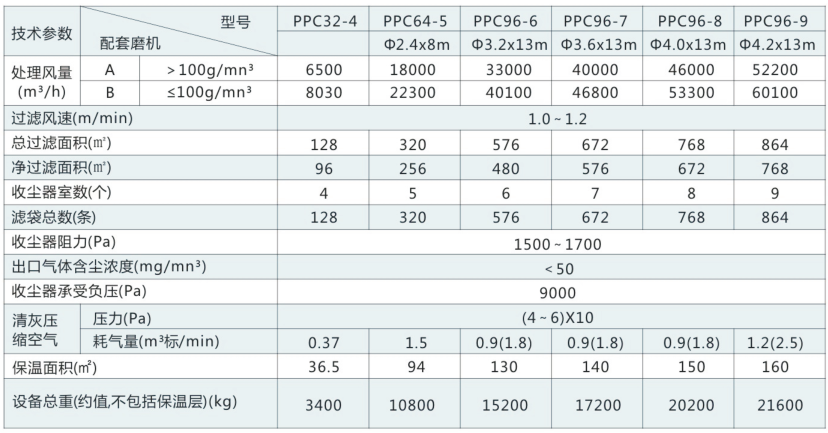

Technical Performance Table of Air Box Pulse Bag Dust Collector