Overview of 0-Sepa High Efficiency Vortex Separator

The improved 0 Sepa high-efficiency vortex separator is a high-efficiency separator developed and produced by our company according to the advanced concept of vortex powder selection, combined with the advanced powder selection technology at home and abroad. It has novel and compact structure, small volume, large processing capacity and high powder selection efficiency; It has the advantages of wide application range, wide adjustment range of product fineness (the specific surface area of the product can be adjusted arbitrarily within 300~650m2/Kg), convenient operation, small maintenance, and more reasonable particle size distribution, which is conducive to improving product quality. Especially with the full implementation of the new ISO cement standard in China, the high-efficiency vortex separator has gradually become the cement loop flow system and the preferred equipment for producing qualified and high-quality cement.

working principle

◆ Under the action of the induced draft fan of the system, the dust laden gas and secondary air from the mill tail enter from the primary and secondary air inlet pipes, and enter the classification room through the air guide blades to form the powder selection air flow. Due to the action of the rotating eddy current blades, the eddy current is formed in the powder selection area.

◆ The materials to be graded are fed from the feed inlet, dispersed by the spreading tray, and then enter the vortex in the powder selection area to form a vortex airflow carrying materials. Materials with different particle sizes in the airflow are sorted under the combined action of suction, centrifugal force and gravity. Fine powder is discharged from the air outlet pipe with the airflow, enters the high-efficiency bag type dust collector outside the machine, and is collected as the finished product.

◆ The coarse powder falls from top to bottom in the powder selection room, falls into the ash hopper after being graded by the primary and secondary air repeatedly, and then is washed by the tertiary air, so that the fine powder in the coarse powder returns to the powder selection area again, and is discharged from the air outlet pipe with the air flow to fully remove the fine powder mixed in the coarse powder. The coarse powder is discharged from the outlet at the bottom of the ash hopper, and enters the mill again to form a closed grinding system.

◆ Grading principle: within the standard range of finished products, fine materials are discharged from the air outlet through the vortex blade with the air flow because the suction force is greater than their own gravity and centrifugal force; Coarse materials outside the standard range of finished products fall naturally or are thrown to the edge wall and fall again because their gravity is greater than other external forces. The product fineness can be conveniently adjusted by adjusting the rotor speed.

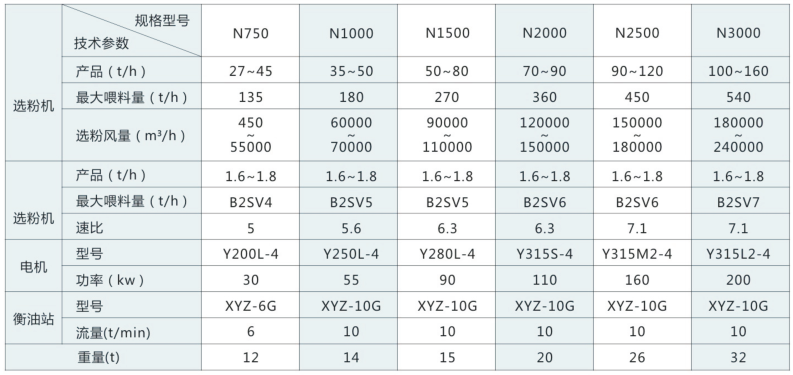

0-Sepa High Efficiency Vortex Separator - Technical Parameters