Main purpose of three cylinder dryer

◆ Three cylinder dryer is mainly used for drying machine - granular materials within the range of constant humidity and particle size, such as yellow sand used for dry powder mortar, blast furnace slag, clay, iron powder limestone used for building materials and cement industry, molding sand of various specifications used for casting industry, silica sand used for glass industry, such as limestone, and small granular materials used in chemical industry that can not withstand chemical changes and are not afraid of high temperature and smoke pollution, According to the requirements of different industries on the moisture content of drying materials, the minimum moisture content of dried materials can reach 0.5~1.5%.

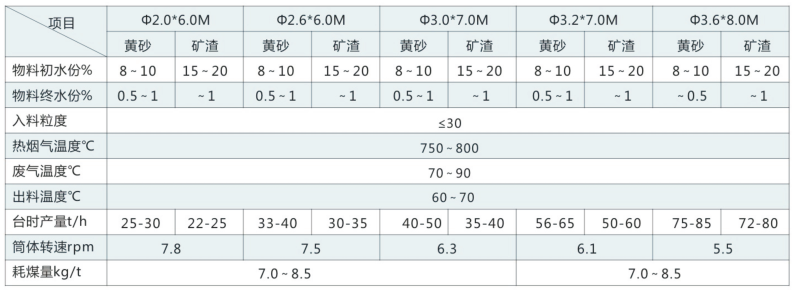

◆ According to the requirements of different industries and different material properties, it is generally appropriate to stick the cylinder wall and lifting plate to the materials entering the three cylinder dryer. The temperature of the heat exchange gas entering the inner cylinder of the three cylinder dryer should not be higher than 800 ° C. If there are special requirements for high temperature, the inner cylinder and lifting plate of the dryer can be made of heat-resistant steel plates.

Structure and working principle

◆ The three cylinder dryer is composed of three concentric circles with different diameters embedded and combined with each other as the main body of the three cylinder dryer. The main body is horizontally placed on the four supporting wheels at both ends through the tires at both ends. Both ends of the cylinder are equipped with sealing devices, the feeding end is equipped with high temperature flue gas fluidized bed furnace type fuel oil, gas fired hot air furnace, and the discharge end is equipped with dust cover and automatic blanking device. The dust cover passes through the equipment and is designed separately according to the requirements of the actual situation of the factory.